In arthroscopic surgeries, precision is paramount—but there’s a silent, often overlooked threat: metal particulate shedding. Recent studies have highlighted the significant dangers posed by metallic microparticles released by common surgical instruments.1 While these particles may be invisible to the naked eye, their impact can be dangerous.

Why Is Metal Particulate Shedding Dangerous?

Research shows that metallic microdebris is shed during arthroscopic procedures at a microscopic level, much smaller than previously recognized. These tiny particles may seem harmless due to their size, but their bioactivity presents a real threat to patients. In vitro studies have demonstrated that these microparticles can trigger an inflammatory response in synoviocytes (cells found in the joint lining).

This response, driven by cytokines—proteins that regulate inflammation—could cause intra-articular damage if the concentration of metallic microparticles becomes clinically significant. Over time, this could lead to complications such as chronic inflammation, joint degradation, or even implant failure, threatening the long-term success of the procedure and patient recovery.

CONMED Shaver Blades Can Reduce Metal Particulate Generation

We recognize the dangers of metal particulate shedding. In an effort to significantly reduce this risk, our shaver blades are designed to minimize metal-on-metal contact and limit the generation of harmful microparticles during surgery.

How it works:

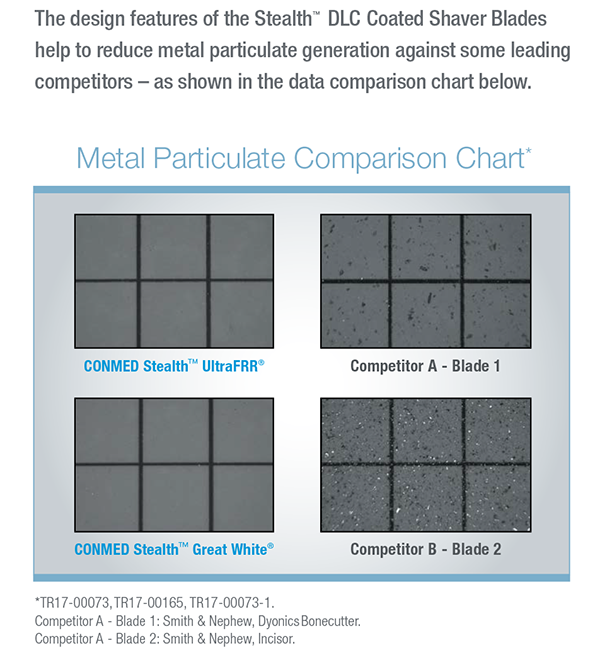

- Diamond-Like Carbon (DLC) Coating: Our shaver blades feature a DLC coating on the distal cutting tip. This advanced material has a lower coefficient of friction than standard steel, meaning it experiences less wear during use. Studies have shown that DLC-coated blades generate fewer metal particulates compared to leading competitors, providing surgeons with a safer, more reliable tool.

- Lubricated Inner Tube: The inner tube of our shaver blades is fully lubricated with full-length shrink coverage. This added layer acts as a barrier to prevent metal-on-metal contact, significantly reducing the amount of particulate generated within the blade shaft.

These innovations allow for a more precise, controlled cut with less risk of particulate release, protecting both the surgical site and long-term patient outcomes.

A Safer Future for Arthroscopy

The risk of metal particulate shedding is a serious consideration for surgeons performing arthroscopic procedures. By choosing tools designed to minimize this risk, you can ensure better outcomes for your patients; reducing the likelihood of long-term joint damage and contributing to a safer future in minimally invasive surgery.

We’re committed to advancing surgical technology that puts patient safety first. Our innovative shaver blades, like the Stealth™ Diamond-Like Carbon (DLC), is engineered to reduce metal particulate generation, allowing you to focus on what matters most—excellent patient care.

Discover Stealth™ DLC

1 Pedowitz RA, Billi F, Kavanaugh A, Colbert A, Liu S, Savoie FH, You Z. Arthroscopic surgical tools: a source of metal particles and possible joint damage. Arthroscopy. 2013 Sep;29(9):1559-65. doi: 10.1016/j.arthro.2013.05.030. Epub 2013 Jul 30. PMID: 23910000; PMCID: PMC3759605.